Diesel Engine Remanufacturing: A Smarter, Sustainable Solution for Engine Failures

Did you know that remanufactured diesel engines can perform just as well as new ones, at a fraction of the cost? Are you looking for a way to extend your engine’s life without breaking the bank?

In today’s world, where cost-efficiency and environmental sustainability are becoming more important than ever, diesel engine remanufacturing is gaining momentum as a practical alternative to engine replacement. Whether you’re running a fleet, managing a farm, or operating heavy construction equipment, engine failure can mean downtime, lost revenue, and costly repairs. But what if you could solve those problems without replacing the entire engine?

Let’s dive deep into why diesel engine remanufacturing might be the best solution for your business and your bottom line.

What is Diesel Engine Remanufacturing?

Diesel engine remanufacturing is the comprehensive process of disassembling, cleaning, inspecting, repairing, and rebuilding a diesel engine or its modules to restore it to a like-new condition, often meeting or exceeding OEM standards.

Unlike simple repairs or refurbishing, remanufacturing involves replacing all worn or damaged parts, rigorous testing, and quality assurance to ensure long-term performance and reliability. It’s an end-to-end process designed to maximize engine life and efficiency.

Read More: What Type of Diesel Engine Computer Do I Need?

Why Diesel Engine Remanufacturing is a Necessity

Engine failures don’t just halt operations; they come with a domino effect of costs and consequences. Here’s why remanufacturing is becoming the preferred route:

Cost-Effective Alternative

Brand-new diesel engines or modules can cost several thousand dollars, especially for large commercial or industrial applications. Remanufacturing offers a significantly more affordable solution, often cutting costs by 30% to 50%.

“Remanufacturing can reduce engine-related costs by up to 50%, making it a smart choice for businesses focused on ROI.”

Environmentally Friendly

Remanufacturing isn’t just smart for your wallet, it’s smart for the planet. It involves recycling usable parts and minimizing waste. The environmental impact of building a new engine is far higher than remanufacturing an existing one.

Sustainability benefits include:

– Reduced landfill waste

– Lower carbon emissions during production

– Less raw material consumption

Availability of Replacement Modules

One of the game-changers in remanufacturing is the availability of pre-programmed replacement modules. These are ready-to-install units tailored to your engine’s specifications. With minimal effort and no need for on-site programming, these modules offer:

– Speedy replacements

– Reliable performance

– Plug-and-play convenience

Services That Simplify the Remanufacturing Process

A great remanufacturing provider doesn’t just rebuild your engine; they offer full-service support that simplifies your experience and maximizes your value.

Core Charge Reimbursement

When customers purchase a remanufactured module, they are often charged a temporary core fee. This fee is reimbursed when the customer returns their original, failed module. It serves two purposes:

– Encourages sustainability

– Helps remanufacturers replenish their inventory for future rebuilds

“We offer cash back for your old module. It’s our way of rewarding sustainability.”

Module Repair and Reprogramming Services

In cases where replacement isn’t viable or cost-effective, customers can ship their faulty module for inspection, repair, and reprogramming. This custom service allows you to retain your original hardware while restoring it to full functionality.

Common services include:

– Electronic diagnostics

– Circuit board repair

– Software reprogramming

– Final performance testing

Trusted Source for Diesel ECM Solutions

When it comes to remanufacturing and control module services, working with an experienced, reliable provider can make all the difference. Diesel ECM Exchange is a trusted name in the industry, offering high-quality replacement and repair services for Diesel ECMs, ECUs, and FICMs. With a focus on precision, customer service, and quick turnaround, they help ensure diesel vehicles return to peak performance with minimal delay.

Diesel ECM Exchange provides pre-programmed control modules tailored to your vehicle’s specifications. Their repair service allows customers to ship their faulty units for professional diagnostics, repairs, and reprogramming. The company also supports sustainable practices by offering a core charge reimbursement program, which refunds part of your payment when the original module is returned. This not only reduces waste but also keeps your maintenance costs down.

Whether you’re an independent repair shop, a fleet operator, or an individual vehicle owner, Diesel ECM Exchange offers a seamless, dependable solution to keep your diesel engine systems running strong.

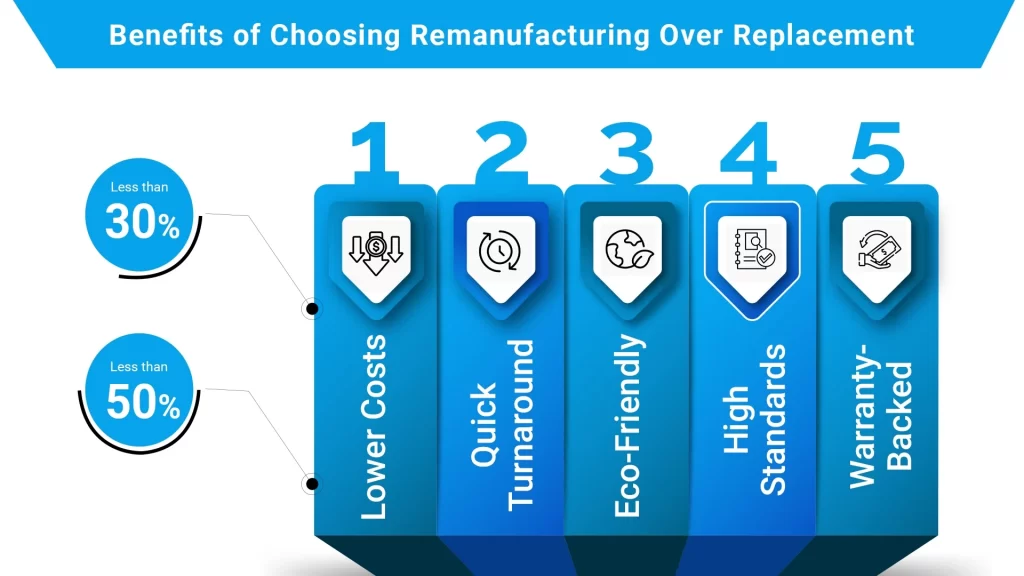

Benefits of Choosing Remanufacturing Over Replacement

Still debating whether to buy new or remanufactured? Here’s a side-by-side of what remanufacturing offers:

– Lower Costs: Typically 30% to 50% less than new engines or modules

– Quick Turnaround: Pre-programmed replacements reduce wait times

– Eco-Friendly: Smaller environmental footprint

– High Standards: Meets or exceeds OEM specs

– Warranty-Backed: Most reputable remanufacturers provide warranties

Who Should Consider Diesel Engine Remanufacturing

Remanufacturing is a valuable solution across a wide range of sectors:

Fleet Operators

Fleet managers need to minimize downtime and reduce operating costs. Remanufactured components with core return and pre-programmed options streamline the repair process and maintain efficiency.

Construction and Agriculture

Heavy-duty diesel engines used in tractors, bulldozers, and excavators are expensive to replace. Remanufacturing keeps equipment running longer with less capital investment.

Independent Mechanics and Repair Shops

Shops can expand their offerings and provide more affordable solutions to customers by partnering with remanufacturers that offer pre-programmed and repairable modules.

How the Diesel Engine Remanufacturing Process Works

Understanding what happens during remanufacturing builds trust and transparency. It is not just a mechanical process; it’s a highly systematic, quality-controlled procedure that transforms a worn-out engine into a unit that performs like new. Here’s how it works in more detail:

1. Initial Core Evaluation

The process begins with receiving the core unit, the old engine or module. Technicians inspect it visually and with diagnostic tools to determine whether it’s viable for remanufacturing. Non-salvageable units are discarded or recycled.

2. Complete Disassembly

The engine or module is fully taken apart down to the last component. All parts are cataloged, and their condition is evaluated to identify which parts are reusable, which require refurbishing, and which must be replaced entirely.

3. Industrial Cleaning

Every reusable part undergoes industrial-grade cleaning to remove oil, carbon buildup, rust, and debris. This step is vital to ensure the precision and cleanliness needed for a successful rebuild.

4. Detailed Inspection and Testing

Cleaned components are inspected for micro-cracks, warping, and dimensional integrity using advanced techniques such as ultrasonic testing, magnaflux inspection, and laser measurement tools. Precision here ensures the reliability of the rebuilt unit.

5. Machining and Component Replacement

Worn parts are replaced with new or reconditioned ones that meet or exceed OEM specifications. Critical components like pistons, bearings, valves, and seals are often replaced entirely. Cylinder heads may be resurfaced, and crankshafts may be ground to precise tolerances.

6. Reprogramming and Calibration

In electronic modules such as ECMs and FICMs, factory-grade software is reprogrammed or updated to match the specific application. This ensures the module communicates accurately with the vehicle’s systems and delivers optimized performance.

7. Reassembly Under OEM Guidelines

The unit is reassembled in a clean, controlled environment using OEM torque specifications and assembly procedures. Attention to detail here ensures longevity and performance under real-world conditions.

8. Final Testing and Quality Assurance

Before being approved for sale, the remanufactured unit is tested using advanced diagnostics and simulated performance conditions. Modules are bench-tested, and engines may be dyno-tested to confirm they meet or exceed OEM performance benchmarks.

This comprehensive process ensures that every remanufactured engine or module is not just repaired, but reborn with a new lifecycle of reliable operation.

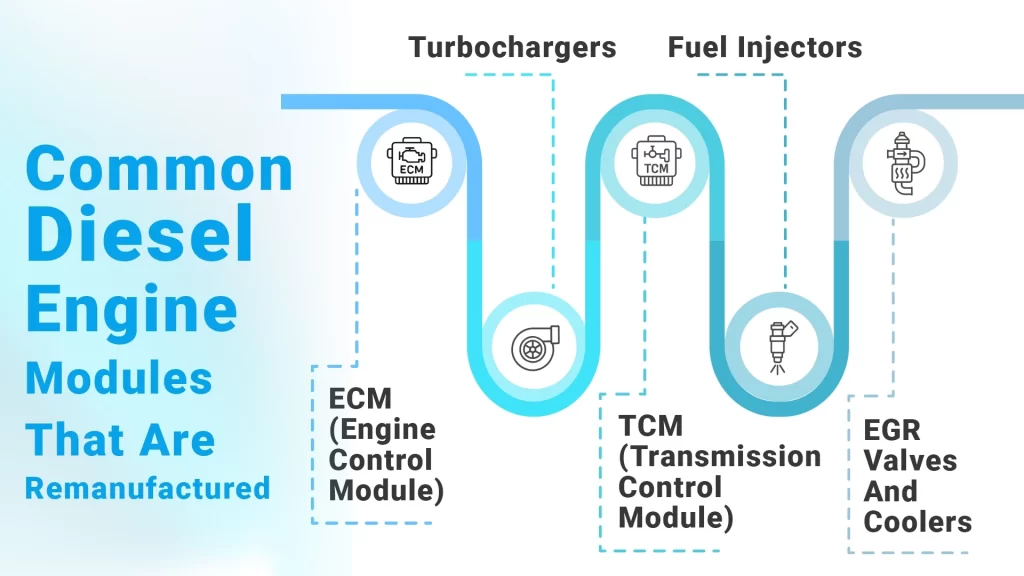

Common Diesel Engine Modules That Are Remanufactured

These are the most frequently remanufactured components in the diesel engine ecosystem:

– ECM (Engine Control Module)

– TCM (Transmission Control Module)

– Turbochargers

– Fuel Injectors

– EGR Valves and Coolers

Most providers offer these parts with core charge reimbursement and repair service options.

What to Look for in a Diesel Remanufacturing Provider

Choosing the right partner can make all the difference. Look for these features:

– Pre-Programmed Options: Cuts installation time and improves reliability

– Warranty Coverage: Reputable shops offer at least a 1-year warranty

– Core Return Program: Refunds that add value

– Customization: Reprogramming for specific engine models

– Customer Support: Technical assistance and responsive service

Real-Life Example: How It Saves You Time and Money!

Imagine your fleet’s ECM fails. A brand-new one costs over $2,000 and takes two weeks to arrive. With a remanufactured ECM:

– You get a pre-programmed unit shipped the same day

– Your core return nets a reimbursement

– Your vehicle is back in service within 48 hours

“The turnaround was so quick, we barely felt the downtime. And getting money back for the old module was a huge plus.”

The Smarter Way Forward

In a competitive and resource-conscious world, diesel engine remanufacturing delivers an ideal balance of performance, cost savings, and sustainability. Whether you choose a ready-to-install replacement module, take advantage of a core return program, or send in a damaged unit for repair, the benefits are substantial.

– Save money

– Minimize downtime

– Protect the environment

If your diesel engine components are failing, remanufacturing may be the smart, responsible alternative you’ve been looking for.